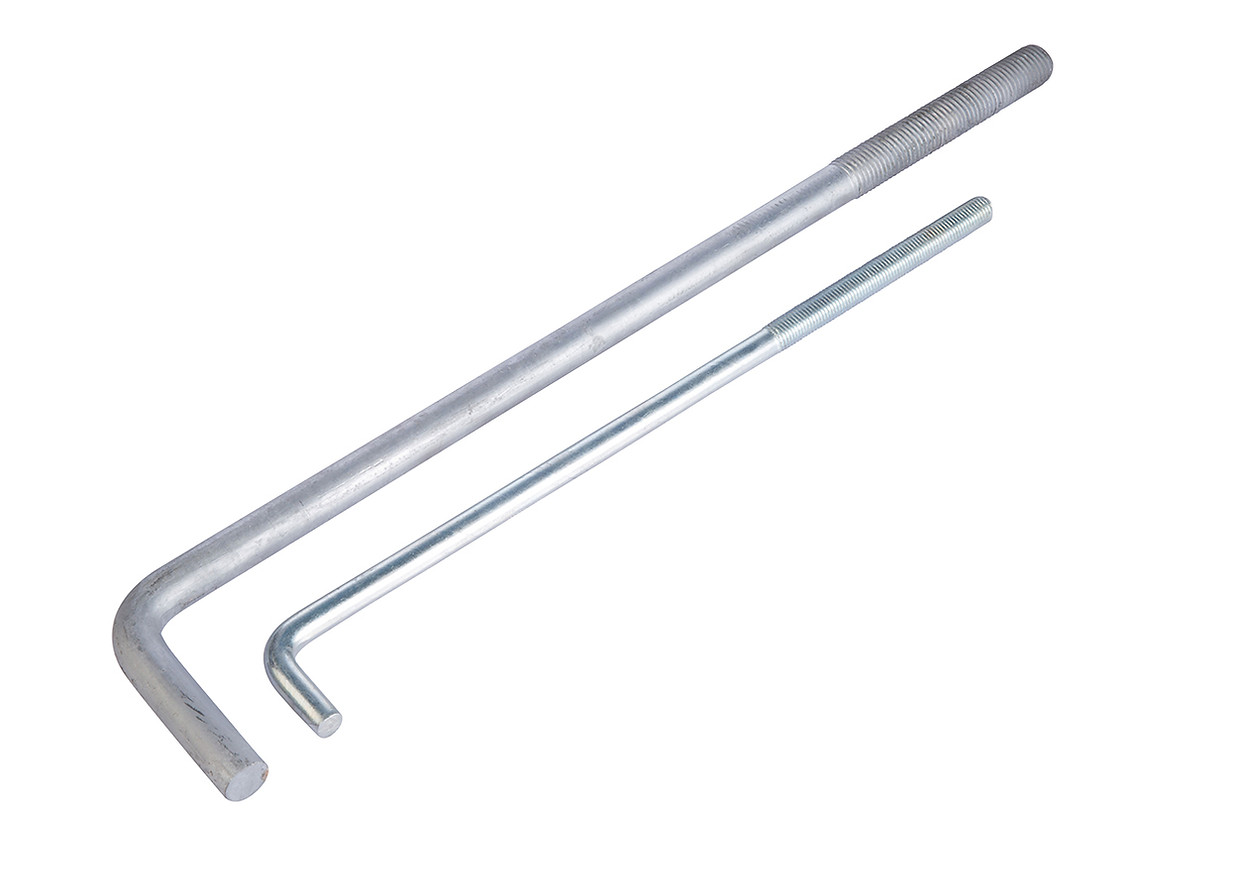

1. Ukusetshenziswa kwama-anchor bolts: 1. Ama-anchor bolts angashintshi abizwa nangokuthi ama-bolts ama-anchor amafushane, ahlanganiswa kanye nesisekelo.Okokulungisa imishini ngaphandle kokudlidliza okuqinile nokushaqeka.

2. Amabhawodi okusetshenzwa kulengwa asebenzayo, awaziwa nangokuthi ama-anchor bolt amade, amabhawodi okusetshenzwa kulengwa akhiphekayo.Okokuvikela imishini esindayo nemishini ngokudlidliza okuqinile nokushaqeka.

3. Amabhawodi okunweba ihange ngokuvamile asetshenziselwa ukulungisa okokusebenza okulula okumile noma okokusiza.Ukufakwa kwamabholiti okunweba okusetshenzwa kulengwa kufanele kuhlangabezane nezidingo ezilandelayo: ibanga ukusuka enkabeni yebhawodi kuya emaphethelweni esisekelo alikho ngaphansi kwezikhathi ezingu-7 ububanzi bebholidi yehange yokwandisa.Amandla esisekelo samabholiti okunweba ihange akufanele abe ngaphansi kuka-10MPa.Akufanele kube nemifantu emigodini ebhoboziwe.Qaphela ukuvimbela i-drill bit ukuthi ingashayisani nepayipi lensimbi kanye nepayipi eligqitshiwe esisekelweni.Ububanzi nokujula kwembobo ebhoboziwe kufanele kufane nebhawodi lokunwetshwa.

4. Amabhawodi okubopha ihange uhlobo lwamabhawodi okusetshenzwa kulengwa avame ukusetshenziswa eminyakeni yamuva.Indlela nezidingo ziyafana namabhawodi okunweba okusetshenzwa kulengwa kuwo, kodwa imfucumfucu emgodini kufanele ishaywe umoya ihlanzeke futhi ingabi manzi.Okwesibili, isimiso sokusebenza se-anchor bolts: 1. Indlela yokushumeka yesikhathi esisodwa: lapho uthela ukhonkolo, ama-bolts wehange kufanele afakwe kuqala.Lapho ukugumbuqelwa kwezakhiwo eziphakeme kakhulu kulawulwa, ama-anchor bolts kufanele angcwatshwe ngesikhathi esisodwa.2. Indlela yokulungisa imbobo: beka okokusebenza endaweni, hlanza imbobo, bese ufaka ibhawudi lehange emgodini.Ngemva kokuba okokusebenza kubekwe futhi kulinganiswe, ukhonkolo wamatshe amahle onganciphi uyathelwa, izinga elilodwa eliphakeme kunesisekelo sokuqala.Ibanga ukusuka enkabeni yebhawodi lehange eliphansi ukuya onqenqemeni lwesisekelo akufanele libe ngaphansi kuka-2d (d ububanzi bebhawodi lehange), futhi akufanele libe ngaphansi kuka-15mm (uma d≤20, akufanele libe ngaphansi. mkhulu kuno-15mm futhi hhayi ngaphansi kuka-10mm).Uma lezi zidingo ezingenhla zingenakufinyelelwa, akumele zibe ngaphansi kwengxenye yobubanzi bepuleti lehange kanye no-50mm.Kufanele kuthathwe izinyathelo ezifanele ukuze kuqiniswe.Ububanzi bamabhawodi okusetshenzwa kulengwa asetshenziswa esakhiweni akumele bube ngaphansi kwama-20mm.Uma ukudlidliza kwenzeka, amantongomane aphindwe kabili kufanele asetshenziselwe ukukulungisa, noma ezinye izinyathelo ezisebenzayo zokunqanda ukuxegiswa kufanele zithathwe, kodwa ubude bokubambelela amabhawodi okusetshenzwa kulengwa kuwo kufanele bube bubude obuyi-5d kunobude obungabambeleli.Indlela yokulungisa ama-bolts we-anchor ngesikhathi sokusetshenziswa ibaluleke kakhulu, kodwa ukusetshenziswa okunengqondo kwama-bolts okunamathiselwe kuzoveza amaphutha afanelekile.Kodwa kufanele ibe phakathi kwebanga elishiwo, vele, kukhona nezinyathelo zokuphepha lapho usebenzisa ama-anchor bolts.Nazi izinto ezine ezibalulekile okufanele uzibheke lapho usebenzisa amabhawodi okusetshenzwa kulengwa.1. Ngemva kokuthi amabhawodi okuhanjelwa kuwo, amakesi namapuleti okusetshenzwa kulengwa angena efekthri, kufanele abambisane ngokuqinile nomkhiqizi, iyunithi yokwakha, isiteshi sokuqondisa ikhwalithi, kanye nomnyango wokugada ukuze bamukele ngokujulile izinga labo, ubuningi kanye nedatha yezobuchwepheshe ehlobene.Noma yiziphi izinkinga ezitholakele kufanele zibikwe kumkhiqizi kanye neyunithi yokwakha ngokushesha futhi zirekhodwe.2. Amabhawodi okusetshenzwa kulengwa, ama-casings kanye namapuleti okulungisa adlule ekuhlolweni kokwamukelwa azogcinwa ngokufanelekile ngumnyango wokuklama impahla.Kumele ivikelwe emvuleni, ekugqwaleni nasekulimaleni futhi imakwe ngokucacile.3. Ngaphambi kokufaka ama-bolts ama-anchor, ochwepheshe bezokwakha kufanele bazi ngokucophelela imidwebo yokwakha, imidwebo yokubuyekeza kanye nezinhlelo zokwakha.Incazelo yobuchwepheshe yamazinga amathathu yabasebenzi bokwakha.4. Ngaphambi kokwakhiwa kwe-formwork, sicela ulungise uhlu lwama-bolt casings ashunyekiwe kanye namapuleti okunamathiselwe ngokuhambisana nezidingo zemidwebo yokuklama.Futhi qaphela inombolo, usayizi, nendawo yokungcwaba (ubukhulu nokuphakama) bese uhlola kabili.